About Us

quality of Liquid Filling Machine, Filling Machine, Viscous Filling Machine, Sealing And Capping Machine, Labelling Machine, Tube Filling Machine, etc (since2013).

We help consumer products companies reduce the packaging cost and societal impact of their product packaging while improving packaging appearance and maintaining product integrity.

Our customers are able to more accurately predict total cost of ownership because of the significant reduction in after-market parts costs through the use hervo controls. They also enjoy higher speed and increased flexibility to change product sizes.

Some words About Us

We would like to introduce our company FILSILPEK Solutions Pvt. Ltd Ahmadabad (India), as leading We are a prominent Manufacturer and Supplier of premium quality of Liquid Filling Machine, Filling Machine, Viscous Filling Machine, Sealing And Capping Machine, Labelling Machine, Tube Filling Machine, etc.

Why FILSILPEK Solutions Pvt. Ltd?

We offer affordable and Durable Packing Machinery and packing automation. With the help of skill employees and long experience in field to reduce labor work and improve output in smarter way as per customized application. We provide you our services within minimum time frame with timely and quality Product.

FILSILPEK Solutions Pvt. Ltd Values

We believe in treating you with the respect we give our co-workers, as a partner in solving your packing challenges. We believe in curiosity, self-improvement, honesty, open communication and collaboration.

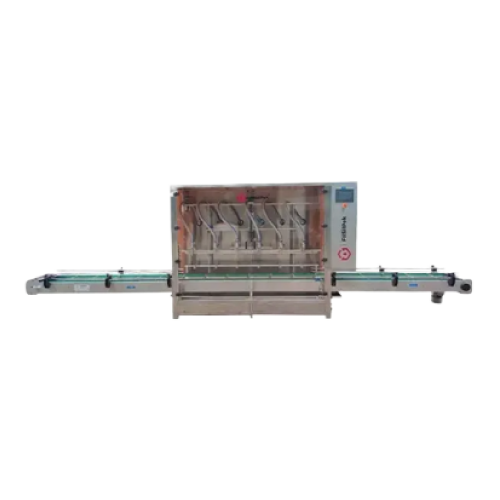

Automatic Oil Filling Machine – up to 1 Ltr

Automatic Volumetric Liquid Bottle Filling Machine works on volumetric principle with diving nozzles. The unit is made compact, versatile and enclosed in stainless steel elegantly matt finish body, consists of S.S. Slat Conveyor, Reciprocating Nozzle with self-centering devices & SS Syringe. No container No filling system arrangement is standard features of the machine.

The main drive of the machine and conveyor drive consist of A/c Motor with synchronized variable A/c Frequency Drive.

Features

- ±1 % Filling accuracy on single dose.

- No Bottle No Filling System.

- All Contact Parts made of S.S.316

- Rigid vibration free construction for trouble free performance

- S.S. Elegantly matt finished body.

- Minimum charge overtime, from one size to another container or fill size.

- Self-lubricating UHMW-PE guide profile for S.S. slat chain provides low friction wear surface, smooth and noiseless conveying.

- Bottle Stopping arrangement through Pneumatic system.

- Synchronized two nos. A/c drives for main motor & conveyor belt.

- Safety guard for conveyor gearbox, motor and pneumatic cylinders.

- Inbuilt protection against over current, voltage fluctuation, short circuit in A/c frequency drive.

- Total GMP model.

Specification

- Filling Range :- 50 ml to 1000 ml

- Output :- 1500 to 3000 per hour

- Direction of Movement :- Left to Right

- Number Of Head / Syringe :- 4 Nos.

- Main Machine :- 1 HP / 415 V / 50 HZ

- Conveyor :- 0.5 HP / 415 V / 50 HZ

- Power Supply :- Single Phase

Application

- Any type of liquid

- Pharmaceuticals

- Juice

- Food Industries

- Liquor

- Oil

- Pesticides

- Distillery

Automatic Oil Filling Machine – up to 5 Ltr

The Electronic PLC Based Filling Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of filling for glass, plastic or Aluminum bottles. The flow of liquid is measured and converted in to electronic signals being controlled by micro computer base circuitry. Minimum adjustment required to set different capacities from 500ml to 5 Ltr with varying containers. The entire range can be set on the same machine without any change parts with help of flow meter pulses.

Features

- No Bottle No Filling System.

- All Contact Parts made of S.S.316

- 6 Filling Stations, space saving design.

- Easy to clean

- Pneumatically controlled nozzles, with ‘No Container No Fill’ arrangement.

- Drip free nozzle arrangement.

- Reciprocating filling nozzle with self-centering device.

- Pneumatically operated bottle stopper.

- PLC Based Operation

- Repeat accuracy of ± 0.2 to 0.5 % for the specified filling range can be achieved.

Application

- Any type of oil industry

Specification

- Filling Range :- 500 ml to 5 Litr

- Output/Hour* :- 700 to 1800 per hour

- Direction of Movement :- Left to Right

- Number Of Head / Syringe :- 6 Nos.

- Direction Of Movement :- Left to Right

- Accuracy :- +/- 0.2 to 0.5%

Automatic Oil Tin Filling Machine

The Electronic PLC Based Filling Machine is compact and highly efficient machine with elegant look. This multi functional multi featured machine meets the GMP requirements of filling for glass, plastic or Aluminum bottles. The flow of liquid is measured and converted in to electronic signals being controlled by micro computer base circuitry. The entire range can be set on the same machine without any change parts with help of Loadcell measurement.

Application

- Oil Filling.

Features

- No Bottle No Filling System.

- All Contact Parts made of S.S.316/S.S.304.

- 4 Filling Stations, space saving design.

- Easy to clean.

- Pneumatically controlled nozzles, with ‘No Container No Fill’ arrangement.

- Drip free nozzle arrangement.

- Reciprocating filling nozzle with self-centering device.

- Pneumatically operated bottle stopper.

Specification

- Filling Range :-15 Kg.

- Output :- 220-240 per hour.

- Filling Operation:- By Load cell base weighing system.

- PLC:- Panasonic/Schneider Make.

- Nozzle controlling:-Actuator through.

- Push Buttons :- Tele Mechanical make.

- Pneumatic Solenoid Valves :- Janatics make.

- Direction of Movement :- Left to Right.

Automatic Bottle capping machine – up to 1 Ltr

Automatic Screw cap sealing machine is versatile, self-supported on stainless steel leg with height adjustable adjustment system. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine.

Features

- No container No cap arrangement.

- SS elegantly matt finished body.

- Single motor synchronizes conveyor, star wheel.

- Adjustable height of conveyor belt, to align with other machine of the line.

- Sealing pressure can be varied to suit different gauges and size of caps.

- Low noise level, low power consumption.

- Self-lubricating UHMW-PE guide profile for low friction wears surface, smooth and noiseless conveying.

- SS cladding or hard chrome plating of all exposed parts to ensure long life and resistance against corrosion.

- Synchronized A/C drives to synchronize, Conveyor, Star wheel and Platform turret & capping bowl.

- Adjustable bottle height gauge for easy and quick setting.

Application

- All industries for inner and outer cap

Specification

- Output/Hour :- 1000 to 3000**

- No. of Sealing Head :- 1 Nos.

- Direction of Movement :- Left to Right

- Main Motor:- 1 HP / 415 Volts / 50 Hz.

Automatic Bottle capping machine – up to 5 Ltr

Automatic Screw cap sealing machine of upto 5 Liter is Suitable for Round pet bottle and HDPE Container. The machine is precision built on sturdy welded steel frame completely enclose in stainless steel sheet and doors are provided to facilitate the servicing of machine. The Machine equipped with vibratory bowl to continues feeding of Cap for online operation on any liquid filling line. Machine suitable for various sizes of Bottles and Plastic Screw Cap with the help of change parts.

Features

- No container No cap arrangement.

- SS elegantly matt finished body.

- Single motor synchronizes conveyor, star wheel.

- Adjustable height of conveyor belt, to align with other machine of the line.

- Sealing pressure can be varied to suit different gauges and size of caps.

- Low noise level, low power consumption.

- Self-lubricating UHMW-PE guide profile for low friction wears surface, smooth and noiseless conveying.

- SS cladding or hard chrome plating of all exposed parts to ensure long life and resistance against corrosion.

- Synchronized A/C drives to synchronize, Conveyor, Star wheel and Platform turret & capping bowl.

- Adjustable bottle height gauge for easy and quick setting.

Application

- Any type of oil industries

Specification

- Output/Hour :- 1000 to 1500**

- No. of Sealing Head :- 1 Nos.

- Direction of Movement :- Left to Right

- Main Motor:- 1 HP / 415 Volts / 50 Hz.

Induction Sealing Capping Machine

High sealing speed, suitable for volume-produce Convenient for use, good sealing quality, work continuously Ejection plastic iron housing.

Application

- Agriculture.

- Food Industry.

- Pharmaceutical.

- Cosmetics.

- Household Cleaning.

Features

- No foil detection system.

- Easy line relocation.

- Plug and play system.

Specification

- Output/Hour :- 1800 to 2400**

- Power :-1.5 KW .

- Direction of Movement :- Left to Right.

- Conveyor speed :- 0-12 Mts./Min.

- Bottle Diameter:- 30-50 mm.

- Bottle Height:- 10-300mm.

- Size :-900mm x 600mm x 1500 mm.

Optional Accessories

- Slat chain conveyor system.

- Pneumatic based no foil bottle rejection system.

- Micro processor based safety interlock system.

Automatic Round Bottle Sticker Labelling Machine

The Automatic Vertical Sticker Labelling Machine is one of the most users friendly. The machine is used for full/partial wrap around labeling on different size of round containers. The automatic model is equipped with roller spacing device resulting in a simple operation with “No change parts required”.

Application

- Pharmaceuticals.

- Oil Industry.

- Pesticide.

- Juice.

- Food Industries.

- Liquor

Chemical. - Distillery.

Features

- High Production Speeds.

- SS steel structure cladded with stainless steel 304 sheet to meet GMP norms.

- Microprocessor Based operation

- Accurate label placement.

- No change parts requirements.

- Very less down time for change over.

- Suitable for Glass, Plastic, Pet, Tin, Corrugated containers.

Specification

- Direction of Movement :- Left to Right.

- Output/Hour* :- 1800 to 3600.

- Controlling :- Micro controller base

- Motor :- Stepper Motor.

Front Back and Round Sticker Labeling Machine

The Automatic Vertical Sticker Labelling Machine is one of the most users friendly. The machine is used for full/partial labeling on different size of flat or rectangular containers. The automatic model is equipped with roller spacing device resulting in a simple operation with “No change parts required”.

Application

- Juice.

- Food Industries.

- Liquor.

- Chemical.

- Distillery.

- Pharmaceuticals.

- Oil Industry.

Features

- High Production Speeds.

- SS steel structure cladded with stainless steel 304 sheet to meet GMP norms.

- Servo PLC Based operation.

- Accurate label placement.

- No change parts requirements.

- Very less down time for change over.

Specification

- Output/ Hour :- 2400 to 4800.

- Direction Of Movement :- Left to Right.

- Controller :- PLC Based control.

- Label Accuracy :- +/- 1mm.

Cooking Oil Pouch Packing Machine

Under the strict supervision of our experienced professionals, we are offering an innovative collection of Single Head Edible Oil Pouch Packing Machine. In this pouch packing machine the filling operation is faster and more stable because the micro pressure filling operation of the new type is adopted.

Features

- S.S Heavy duty Body

- Leakage free Operation

- +/- 1% accuracy

- High Speed

- Feeling Volume Adjustable without Change part

Specification

- Filling Range :- 500 ml to 1000 ml

- Output/Hour :- 900 to 1000

- Sealing :- Side Sealing

Application

- Oil Industries